VA History

History of the Cash Still and the Volatile Acidity Still (RD80)

|

The early volatile acidity testing was done with an assortment of glass parts cobbled together with stoppers, rubber tubing, and a Bunsen burner. The critical part was a so-called Sellier tube, which provided a means of feeding steam into the wine to be tested. However, the speed of operation varied considerably, depending on the exact setup, the available Bunsen burner, and so forth. The State of California required more repeatable and consistent testing, and this assembly did not meet the standards. |

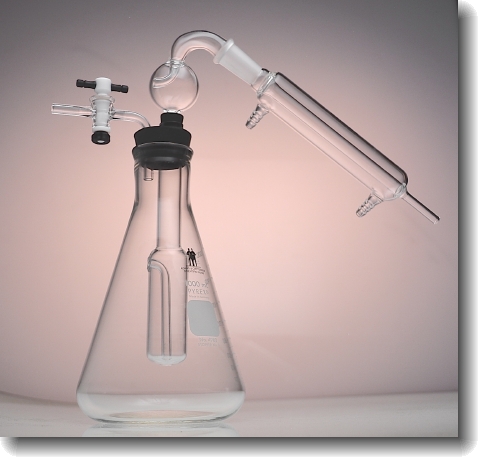

Modified Hortvet-Sellier Distillation Apparatus |

|

The next iteration of apparatus was the Cash Still, shown on the right, devised by Lyman Cash at Gallo Winery. The history is a little fuzzy at this point; the glassware was brought to reality in the early 1950's by Hank Rhodes and Tom Tait at Western Scientific, a scientific glass shop in Berkeley. This concatenated all of the previous glass parts into two parts: the body, comprising a boiling flask with an electric heating coil to generate steam, a chamber wherein the steam passes through the wine sample, a distillation vapor trap, a double oblique stopcock with funnel to introduce the sample or add distilled water; and a separate condenser. In use, the wine sample is poured into the center chamber, and the power turned on to the heating coil immersed in distilled water. The stopcock is opened to atmosphere; when the water boils, the stopcock is closed to direct the steam through the wine sample. The vapors pass through the distilling trap and crossover arm to be condensed in the Graham condenser. 100 ml of distillate is collected, then titrated to determine the total volatile acidity. At the end of the process, the drain is opened and the hot water dumped out, siphoning the old wine sample out in the process. Fresh distilled water is added, a new sample poured in, and the cycle begins again.

The heating coil and cordset, and connection to the boiling flask have gone though a number of configurations, as well. For many years, we used Pyrex baby bottle threads, the plastic threaded cap rings, and a rubber stopper with two threaded posts to seal and connect to the heating coil. Baby bottles were an excellent, cheap source of thread, but plastic took over from glass; that source dried up. Corning made a "milk dilution bottle" with the same thread, but a square cross section, which made an adequate, but annoying substitute. We had to cut the thread pretty short to avoid the square section. Of course, Corning, in its corporate wisdom, changed the formulation of the glass to one which is not compatible with our usual borosilicate glass, so we couldn't use the milk dilution bottle either. Eventually we began tooling our own threads.

Older stills having the obsolete thread and cordset can be retrofitted for the new version.

A few years ago we at Adams & Chittenden Scientific Glass decided to re-engineer the whole cordset and connector, basing the connection on the GL45 thread, which is a standard, rather beefy thread, in common use in the chemistry and biology worlds. We designed a stopper, with stainless steel posts to connect to the heating coil. This has proven very effective, avoiding many of the leakage, corrosion, and disconnection problems common in the older version.

|

Below, the redesigned VA Still features a built-in aspirator

|