Special Projects: Glass Echem Flow Cell

This was a challenging project, design-wise as well as in several aspects of fabrication. Shown on the right are the two halves of the glass echem cell designed for research into membrane materials. Below is the researcher's initial idea, sent to us as an email.

Concept to glassware ensues...

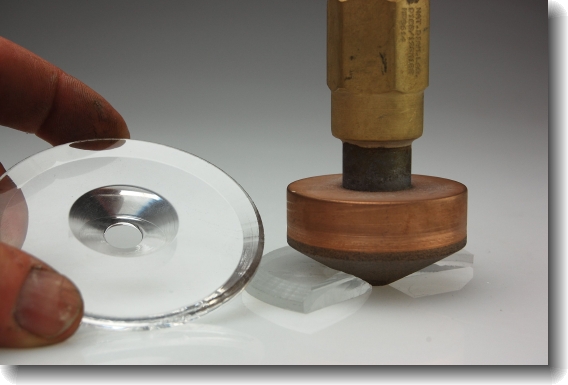

The parts required diamond tooling. The researcher requested a specific internal profile at the membrane contact opening. And the knuckle clamps require an outside bevel to help center the clamp on the flanges.

An initial problem to solve was the need for a small opening between halves while maintaining minimal volume. Yet both halves require a lot of porting.

Another issue was how to hold the halves together and effect the membrane seals, while maintaining axial alignment. We decided to try the NW glass flange clamping system utilizing a knuckle clamp. This provided better alignment and more even clamping pressure than the original proposal.

Challenging, but successful! The client was happy, and we got a good workout.

Client emails;

"That cell looks incredible!!! You've done an impressive work!!!

The cell itself is just a "regular" electrochemical flow cell with some specific parameters e.g. central opening is the same size as the electrode surface. It sounds so simple but, in fact, it is very hard to find a glass product with such specification. Thank you for your effort."