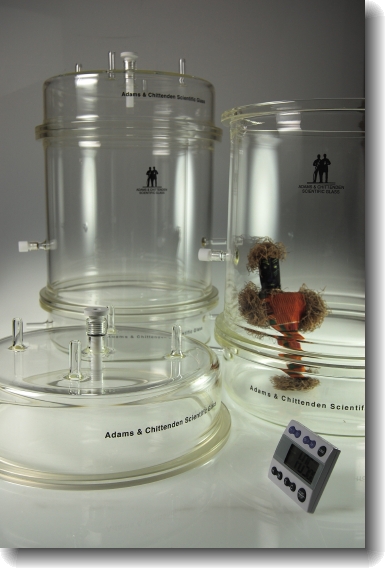

Special Projects: Silanized Exposure Chambers for Environmental Testing

You see pictured here some rather large borosilicate chambers that have been silanized, post fabrication. The client had a contract for evaluating passive air samplers for indoor air and soil gas, and needed to achieve high levels of accuracy in a custom-made exposure chamber in order to execute laboratory studies before performing field validation work. They had worked out the basic arrangement using a 5 gallon plastic tub, and it was time to get serious about "clean".

After the glassware was complete, they were sent out for silanizing by another company. Shown above is the glassware after being treated with this chemical vapor deposition process. Silanizing is used to enable low levels of compounds to be accurately sampled and analyzed, by a surface treatment which eliminates surface adsorption of active compounds on glass. The client was kind enough to send us these pictures of what the glass chambers look like after this processing.

These chambers were formed from 315mm OD Schott tubing, pretty close to the largest borosilicate glass tubing available, and also pretty close to the ID of that plastic tub. We tooled the flanges, and positioned the fittings to accommodate their procedures. You can see more glass chambers here.

At this point, our part of the project was complete, or so we thought...

The client had some further requirements. In addition to the chambers, we were asked for some "vapor generators", an aspect of their project that had not been scheduled, let alone designed. We started with a 1L media bottle prototype, and were quickly able to provide the 2nd iteration, complete with modifications and larger capacity.

1L prototype

5L vapor generator

“We are very pleased with the level of service provided to us by Adams and Chittenden in the design of exposure chambers for our vapor intrusion studies. Tom Adams was extremely helpful in providing us with information regarding the capability and limitations of glass, so that together we were able to create an apparatus that served our purposes. The chambers were provided to us on time and on budget, and the overall customer service was excellent. We would not hesitate to use A&C again.

Hester Groenevelt

Project Manager